Grease Trap Installation Services Overview

Visitors can learn about grease trap installation services and compare local contractors who handle the work.

- - Commercial property owners seeking efficient grease trap installation solutions for restaurants and foodservice facilities.

- - Residential property managers or homeowners needing professional grease trap setup for multi-unit buildings or private properties.

- - Business operators looking to connect with local contractors experienced in installing grease traps for food establishments.

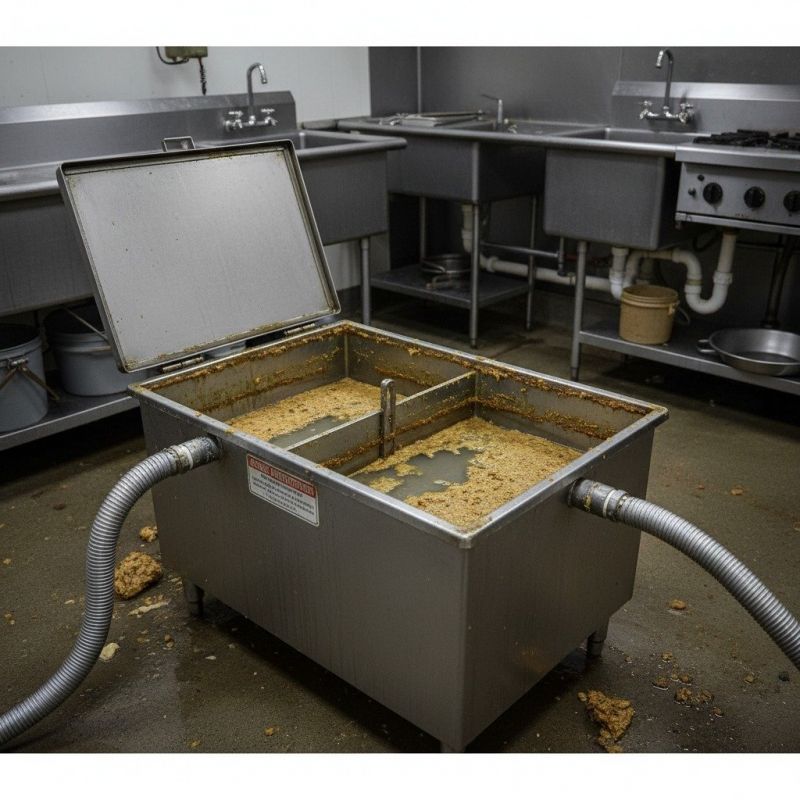

Grease trap installation is a specialized service often needed for commercial kitchens, food processing facilities, and other establishments that handle significant amounts of cooking waste. Property owners seeking this work typically look for experienced local contractors who understand the specific requirements for proper installation, maintenance, and compliance with local regulations. These professionals assess the property’s needs, select appropriate grease trap units, and handle the installation process to ensure the system functions effectively and efficiently.

Local service providers in this field offer a range of installation options tailored to different property types and operational demands. They are equipped to manage the complexities involved in integrating grease traps into existing plumbing systems, often providing guidance on optimal placement and size. Property owners can expect to connect with knowledgeable local contractors who prioritize quality workmanship and reliable service, helping to ensure that grease trap systems are installed correctly and operate smoothly over time.

This guide provides helpful information to understand the key aspects of grease trap installation projects. It assists in comparing local contractors and understanding the basics needed to plan a job effectively. By using this resource, visitors can better prepare to connect with qualified service providers in their area.